Whei processing and ricotta

Flocculation Vats

Flocculation vats are suitable for big productions of industrial ricotta. They are heat-insulated and made in stainless steel AISI 304. Bottom and side are jacketed to increase temperature and reach flocculation temperature. Conical bottom to permit an easier ricotta discharge. Optional: direct steam injection on the bottom of the vat.

Horizontal continuous flocculators

Flocculators are machines for producing cottage cheese in large quantities. They are closed, insulated tanks with steam injection on the bottom and wall, with a highly tapered bottom for easy discharge. Direct steam injection on the bottom of the tank can be supplied as an option. They are CIP washable.

Hot Water Equipement

TECNOLAT, for ricotta draining and drying, provide a vat, entirely made in stainless steel AISI 304, with a belt system that ensures the desired draining and drying of the product.

Semispherical Double Jacketed Vats With Pressurized Steam Circulation

The semispherical double jacketed vats, made in stainless steel AISI 304, allows a quick whey heating, and the particular shape improves the natural outcropping of the product. The ricotta outcrops in a natural way (only with the heat). The vats can be either fixed or overturning.

Cradle Double Jacketed Vats

Made in stainless steel AISI 304. The shape (semicylindrical) allows optimal heating of the product, also thanks to the introduction of a steam diffuser along the longitudinal axis of the vat. It is also used for milk coagulation in the production of soft cheeses. The particular geometry reduces the dimension.

Whey Heat Exchanger

TECNOLAT heat exchanger allows to reach the whey optimal temperature before ricotta production.

Skimmers

TECNOLAT commercializes various models of skimmers, for many dairy industry applications.

Ricotta Collecting Platforms

TECNOLAT ricotta collecting platforms are entirely made of stainless steel AISI 304.

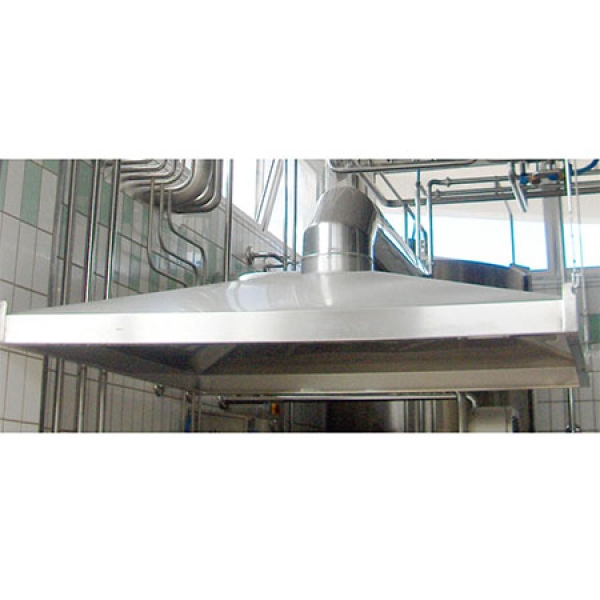

Extractor hoods

Extractor hoods are made of AISI 304 stainless steel and are used to prevent the formation of steam and related condensation inside the processing room.